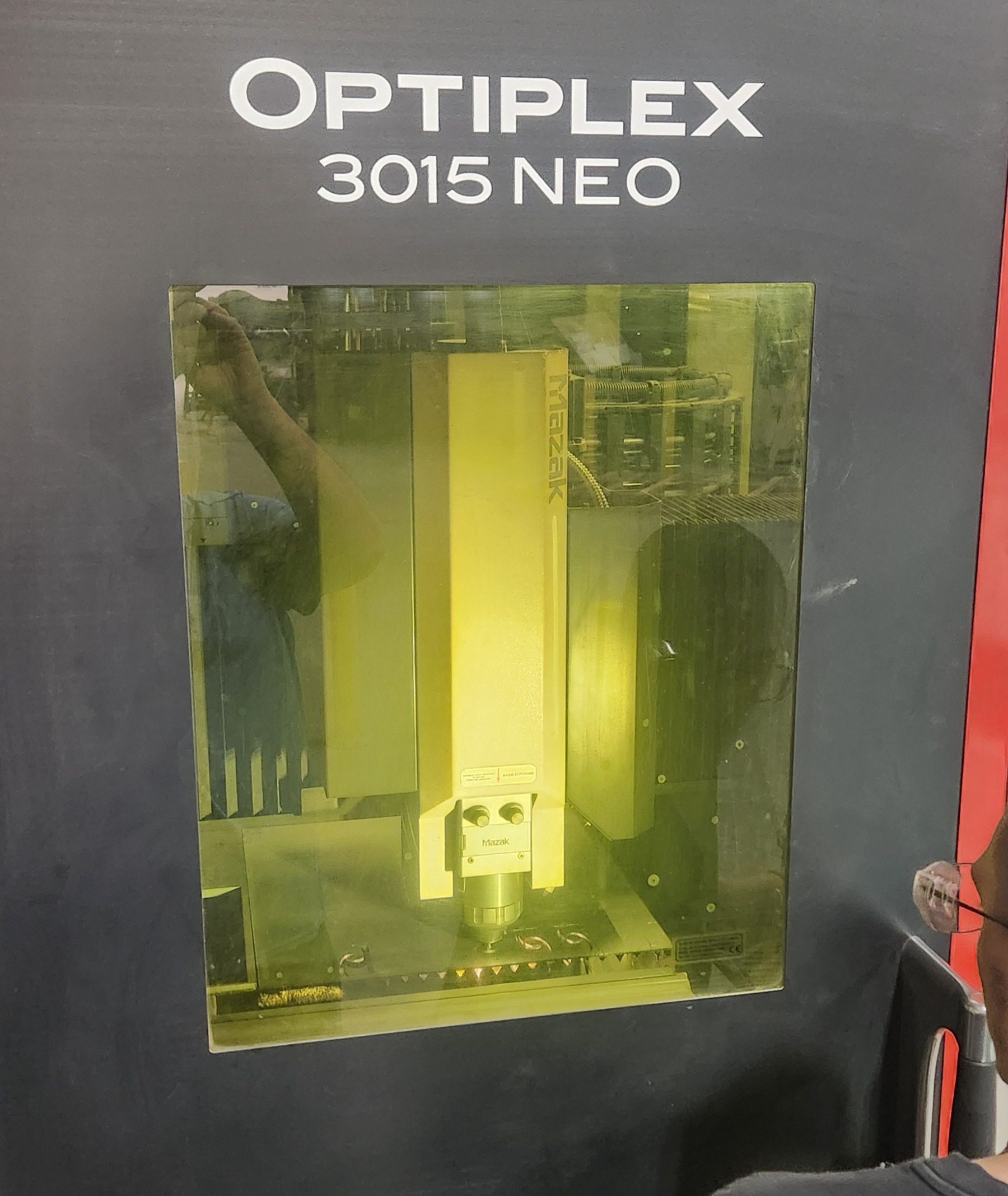

At Schock Manufacturing, our laser cutting services are designed to provide the highest level of precision and efficiency for a wide range of applications. Utilizing state-of-the-art technology, we ensure that every cut meets the exact specifications required for your project.

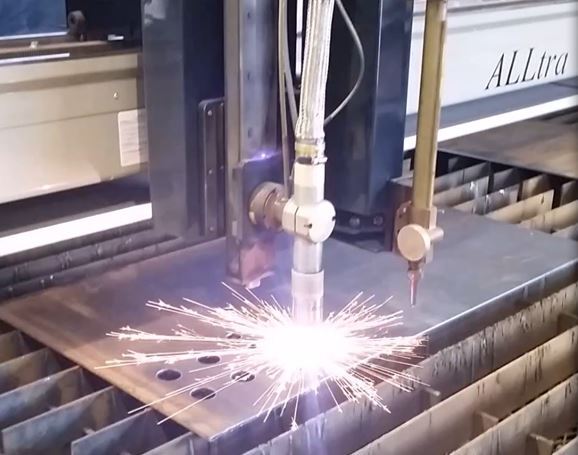

Our laser and plasma cutting capabilities are designed to meet the needs of even the most demanding projects.

We can handle:

- Material Thickness: From thin sheets to thick plates, we can cut materials of various thicknesses with precision.

- Cutting Area: Our equipment can accommodate large sheets and complex designs, ensuring flexibility in production.

- Material Types: We work with a wide range of materials, including steel, aluminum, stainless steel, brass, copper, and more.

- Complex Geometries: Our technology allows for the cutting of intricate shapes and detailed patterns with high accuracy.

Laser/Plasma Cutting Capabilities

Industries We Serve

Our laser cutting services cater to a diverse array of industries, including but not limited to:

Energy:

Energy:

Components for energy generation and distribution systems. Electronics:

Electronics:

Intricate components for electronic devices and systems. Construction:

Construction:

Custom metal components for building and infrastructure projects. Automotive:

Automotive:

High-quality parts for vehicles, from prototypes to production. Medical:

Medical:

Precise and reliable parts for medical devices and equipment. Aerospace:

Aerospace:

Precision components and parts for aircraft and space exploration.

Why Choose Schock Manufacturing for Tulsa Laser Cutting?

- Unmatched Precision: Our advanced laser technology ensures clean, accurate cuts with minimal waste.

- Cost Effiency: High-speed cutting reduces production time and costs, delivering excellent value.

- Versatility: Capable of cutting a variety of materials, including metals, plastics, and more.

- Quality Assurance: Rigorous quality control processes ensure every part meets your specifications.

- Experienced Team: Our skilled operators and engineers bring years of expertise to every project.

At Schock Manufacturing, we are dedicated to delivering top-quality plasma and laser cutting services that meet the highest industry standards. Contact us today to discuss your project requirements and discover how we can help you achieve your goals with precision and efficiency.

Contact Us