Gas Turbine Exhaust Plenum

Gas Turbine Plenum : GE MLI 1625 (EXHAUST PLENUM) 5, 6B, 7B, 7C, 7E, 7EA

EXHAUST PLENUM OVERVIEW OF LINER SYSTEM

Schock Plenum's

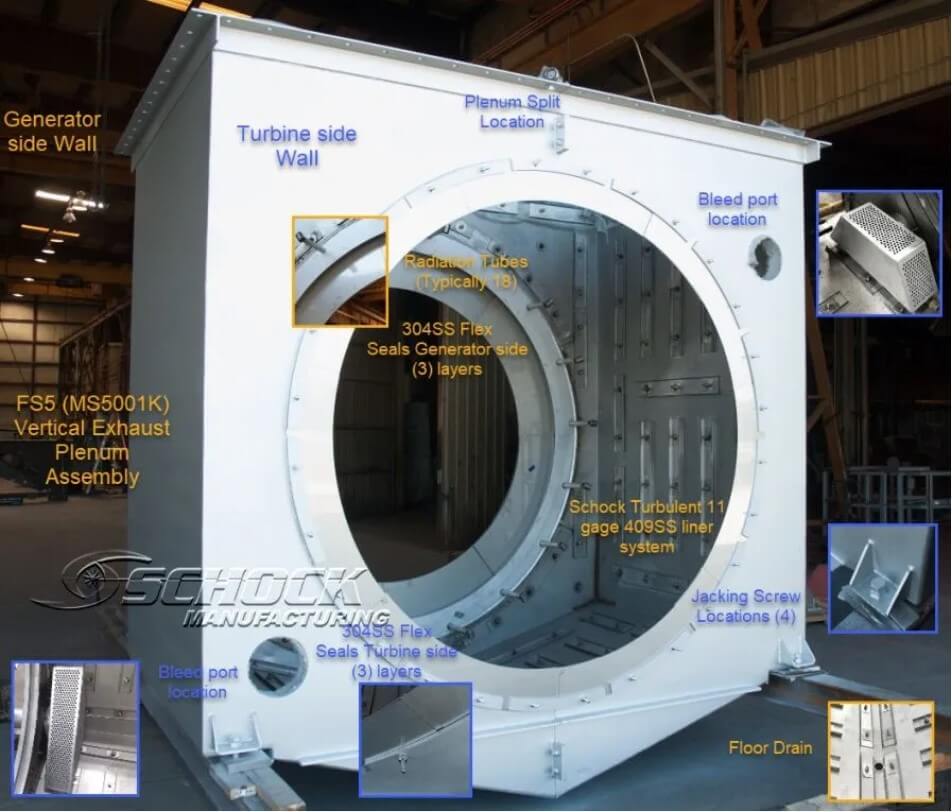

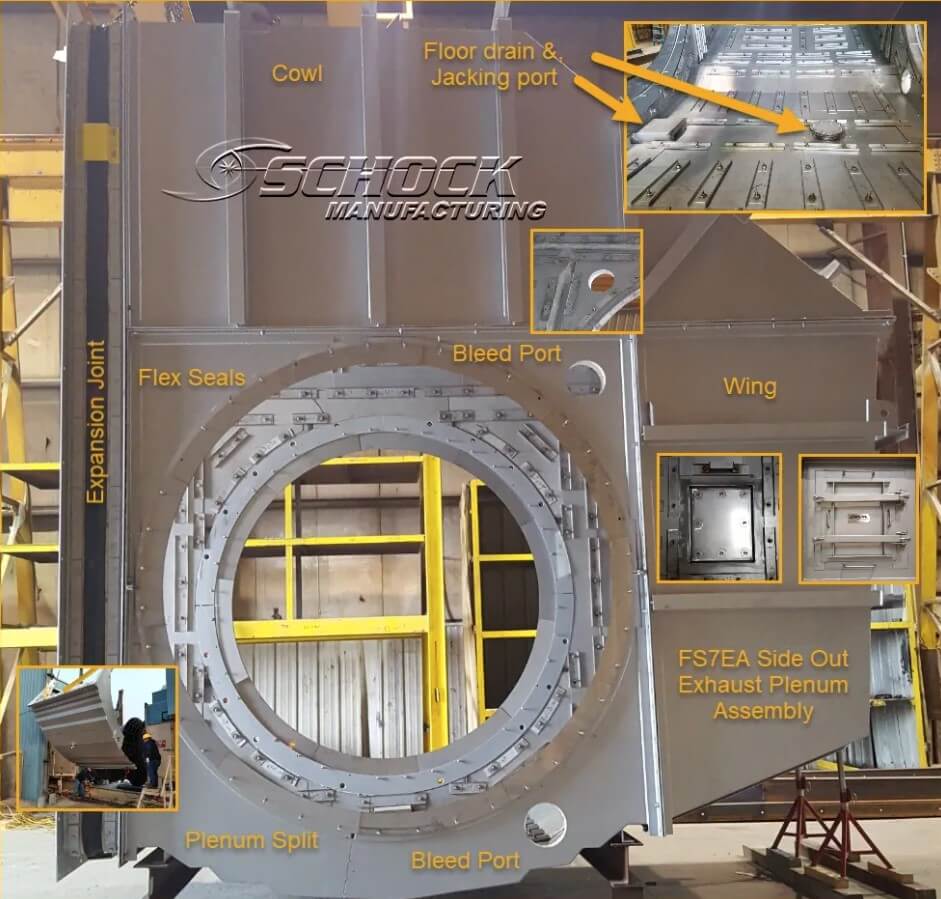

The Exhaust Plenum is used on GE radial Gas Turbines. The plenum essentially acts as an "enclosure" or Exhaust duct at the back of the Gas Turbine frame. This assembly aids in directing flow, left, right, or up to the downstream Exhaust system. There are many critical interfaces or sealing points to the diffuser, frame, and Enclosures. Schock has made countless improvements to the Frame Size 5, 6, & 7 Exhaust Plenum Assemblies. The design maximizes insulation thickness, while not causing critical interference/interface problems. We have the most robust internal liner system on the market today, and do not take any shortcuts! This area of the Exhaust system is critical ducting with very close tolerances. Interfaces to the Enclosures, Diffuser, frame, and Turbine base areas are perfected.

Book your free Exhaust Plenum inspection

If you would like Schock's inspection team to come to your site and evaluate your current Exhaust Plenums condition, please click link below.

Book Your Free Inspection

|

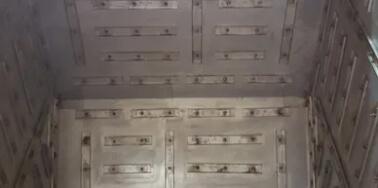

High Turbulent LinerAt the heart of our system is our proprietary liner system. The system starts with large diameter stainless steel liner studs, hand welded to the casing plate at a close pin spacing pattern. Followed by liner support hardware, and 11 gauge 409 SS liner laser cut to perfection. We secure in place with complete clamping channel coverage at all stud locations and complete with our nut torquing procedure to ensure no voids in liner laps but allows for thermal movement. Our "cold" liner system is also applied at all field joints, to ensure consistent casing temperatures. |

|

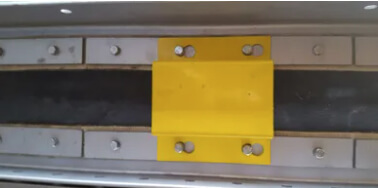

High Temperature Expansion JointOur High temperature Exhaust Belt is hand made with the following components: The outer flexible element is a polytetrafluoroethylene/fiberglass reinforced laminate that is fully insulated for thermal protection. In addition, the outer cover contains a gas seal barrier that eliminates leakage through the belt. Our belt assembly uses an additional layer of Calcium magnesium silicate insulation, tetraglass protection flange cuffs and 304SS screen wire. |

|

SS Radiation TubesOur Stainless Steel radiation tubes are proprietary and hand fabricated for accuracy and strength. We know these tubes are used to "climb" on during inspections, so we ensure their strength to maintain accurate operational measurements. |

|

Floor drains & Jacking PortsWe can provide Jacking ports, external jacking screws, and floor drains to customer spec. |

|

Split designsOur Plenum designs are split to allow for installation without removing the exhaust diffuser. |

|

Bleed Pipe DiffusersStainless Steel bleed pipe diffusers at your standard location/s. |

|

Superior LinerSuperior clamping, superior pin spacing & diameter. Our liner system has been perfected and is carefully designed, assembled and installed each instance. |

|

Enhanced External FlangesStructurally improved flange designs. |

|

Access DoorsThe Schock door is a double seal, no tool design to access the unit. All hardware is Stainless Steel and can be adjusted for complete gas seal. |

PLENUM FEATURES

-

Maximum Insulation for Cooler casing plate

We use high temperature insulation man-made vitreous fiber based on calcium, magnesium, silicate composition. It has excellent thermal performance, and superior wetting resistance. The shop installed insulation is pre-staggered to ease field installation and ensure no through splices.

-

Stainless Steel liner system

At the heart of our system is our proprietary liner system. The system starts with large diameter stainless steel liner studs, hand welded to the casing plate at a close pin spacing pattern. Followed by liner support hardware, and 11 gauge 409 SS liner laser cut to perfection. We secure in place with complete clamping channel coverage at all stud locations and complete with our nut torquing procedure to ensure no voids in liner laps but allows for thermal movement. Our "cold" liner system is also applied at all field joints, to ensure consistent casing temperatures.

-

Stainless Steel Flex Seals

Our flex seals are laser cut to the O.E.M. specification and can be supplied from 300 or Inconnel materials.

-

Insulation pillow enhanced flex seal interface

Schock can provide an insulation pillow kit that protects the flex seal area and further reduces heat loss, and reduces the operating temperature in the generator compartment.

-

Expansion Joint

Our High temperature Exhaust Belt is hand made with the following components: The outer flexible element is a polytetrafluoroethylene/fiberglass reinforced laminate that is fully insulated for thermal protection. In addition, the outer cover contains a gas seal barrier that eliminates leakage through the belt. Our belt assembly uses an additional layer of Calcium magnesium silicate insulation, tetraglass protection flange cuffs and 304SS screen wire.

-

Jacking Ports & Floor drains

The FS5 Exhaust Plenum has external jacking screws on each corner for ease of leveling into place, the FS6 & FS7 can be ordered with optional jacking port to allow lifting access from the turbine base to level into place. All Exhaust Plenum Assemblies are designed standard with a floor drain in the low point of the Exhaust Plenum.

-

Bleed Port Diffuser

Schock has designed the bleed port interface into the "common" area's from previous GE designs. These locations can be customized as required for customer preference. The FS5 and FS6 Exhaust Plenum Assemblies also internal Stainless Steel Diffuser outlets to distribute the gas stream.

-

Plenum Horizontal Field Splice

Schock has developed a structurally enhanced flange bolting interface to strengthen the horizontal flange and eliminate "bowing" or "warping" of this horizontal interface.

-

Access Door

For the FS7 designs, Schock provides a wing mounted access door to access the wing side of the diffuser area. This access door proves critical for diffuser inspections, and can often be visually inspected without going in.

-

Field Hardware & Installation Instructions

We ship a complete kit of materials to ease installation time and effort. All flange gaskets, insulation, liner, hardware, & misc.

FS5 EXHAUST PLENUMS

Schock has made countless improvements to the Frame Size 5, 6, & 7 Exhaust Plenum Assemblies. The design maximizes insulation thickness, while not causing critical interference/interface problems. We have the most robust internal liner system on the market today, and do not take any shortcuts! This area of the Exhaust

FS6 EXHAUST PLENUM

Schock has a proven design that stands the test of time. We have drastically extended the lifespan of this assembly by incorporating cost effective design improvements. We can offer turn-key or equipment only.

FS7B, C, E, & EA EXHAUST PLENUMS

We will interface our Expansion Joint to your H.R.S.G. Inlet duct or Exhaust Transition. We STOCK these assemblies in our Central US workshop, and can generally ship in weeks.

EXHAUST PLENUM VIDEO'S

-

FS7EA Exhaust Plenum Shop Test Erection

-

FS6 Exhaust Plenum Shop Test Erection

-

FS7EA Exhaust Plenum Floor Removal

-

Rolling FS7B Exhaust Plenum Under Diffuser

-

FS6 Exhaust Plenum Wall Installation

-

FS6 Exhaust Plenum Base Install

-

FS7B Rolling Exhaust Plenum Under Diffuser