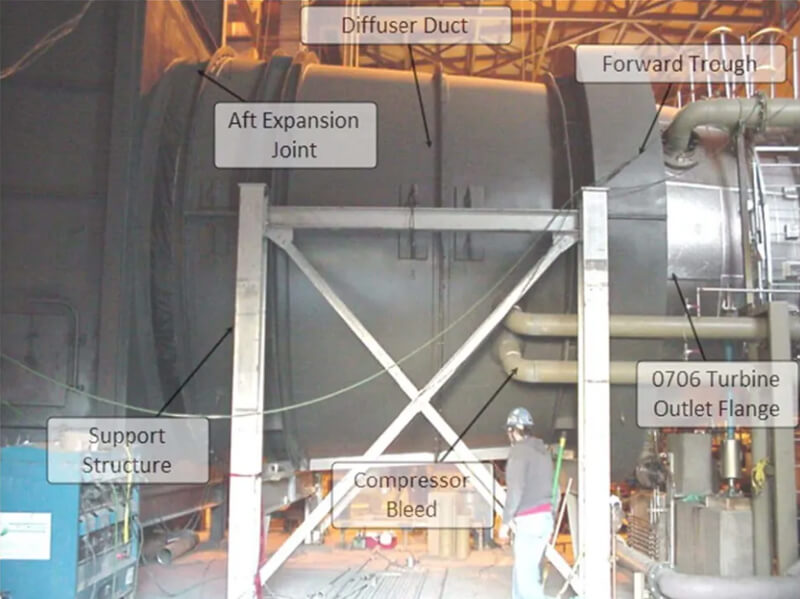

FS7F Diffuser Duct

SCHOCK 7F DIFFUSER UPGRADES

The GE FS7F conical (internally lined) diffuser dates back to the early 1990's. There are 800+ installed in the US alone. Many of these units were installed during the power generation "boom" in the late 1990's and continue perform today.

FS7F Diffuser Duct Purpose

The A042 is an internally lined diffuser duct that attaches mechanically to the aft Turbine Frame flange. It is designed to thermally grow axially/radially approximately 3", and has an outer casing plate temperature of approximately 160F (depending on environment). Flex seals then attach to the A042 flange and are "clamped" inside the diffuser trough to allow for these thermal movements.

This duct diffuses the exhaust gases at a slight angle to reduce turbulence and flow. There are some inherent problems that can occur without proper maintenance and specified initial installation.

Additionally, there is an integrated Expansion Joint (soft belt) on the aft end of the diffuser that also requires proper maintenance and care. All GE 7F Frame Combustion Turbines use this internally lined diffuser duct.

Book your free Exhaust Diffuser inspection

If you would like Schock's inspection team to come to your site and evaluate your current Exhaust Diffusers condition, please click link below.

Book Your Free InspectionDIFFUSER DETAILS

|

Forward TroughThe Forward Trough is designed to accept an internal "seal" from the inside face of the trough to the Gas Turbine outlet flange. Schock offers gasketing, liner, and design upgrades to this area. |

|

Flex SealsThe Forward Trough flex seals are multiple layers of heat treated Inconel. With staggered installation, multiple layers, and varying thicknesses, these seal the hot gases internally. We offer "in kind" replacement kits, as well as design and material upgrades. |

|

Internal Liner systemThe internal liner system design is critical to the performance and protection of thermal insulation. Schock offers upgrades that reduce liner sheets laps, and increases reliability. |

|

Aft Expansion JointThe Aft Expansion Joint can be easily upgraded with a complete high temperature insulation pillow assembly, high temperature Expansion Joint outer belt, and all associated hardware. |

|

Forward Trough Exterior SealThe Exterior Forward Trough can be upgraded with a simple to install "kit" also consisting of multiple high temperature insulation pillow assemblies, high temperature Expansion Joint outer belt, and all associated hardware. |

|

Critical to QualitySchock uses large diameter liner studs precision located with a "jig" and hand welded into place on a close "grid" spacing. The insulation and liner systems are carefully designed and installed for maintenance free operation. |